Development phase 1

Preamble

Hoping that I don’t provide a good enough data-set to fine-tune an LLM to emulate my rambling…

This blog post is intended as practice for documentation and also as a record of ‘things done’, in an effort to break out of the horse-blinkers of doom, which perhaps many entrepreneurs experience in precarity. Or, as I keep dyslexically fumbling around in the non-strict linguistic goop of English: ‘enTRAPeneurship’.

Anyway, thinking ahead as I try to solve my search engine optimisation: I will find some synergy posting for my insta and on my youtube, aiming to become, ideally, like Mixtela.

While thinking about youtubers and metacommenting: some folks out there, like the PCB motor guy, got to have the youtube following and then started looking at commercialising and selling their engineering product. I’m going the other way around, update follows.

Market Personas:

Received advice to think about the personas of the people I am trying to market to, however this blog post is long enough without me elaborating on that!

Small, Medium, Large

The above colleague is developing lights: I passed on my father’s advice: make a small, medium, and a large version of their product. I have offered to sell their stuff on my stalls.

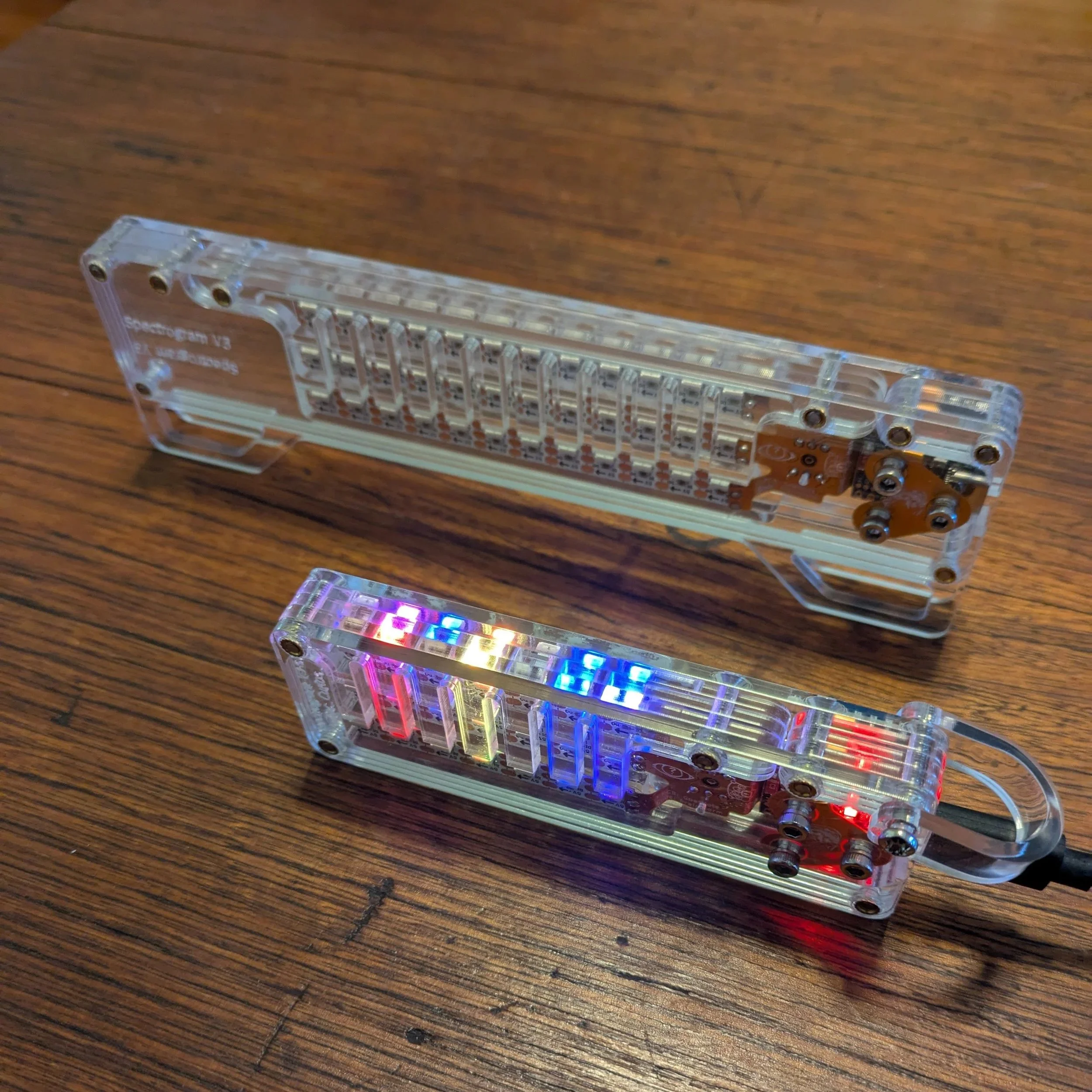

Following my father’s advice: I have been looking to making product derivatives: introducing the small spectrogram, 7 LEDs, 7 octaves total.

The question remains on whether the large is 18 pixels or 24.

Tangles

Continuing to value add to acrylic: I have been getting really into thermo-forming. I am developing and learning about light transfer in bent acrylic. These are somewhere between the new coloured plastic strip LED and laser cut signs, and edge-lit LED signs.

I have also been resisting the urge to follow my heart in recreating the wooden base moodlight, focusing on an MVP that is all laser cut. I have developed an MVP, see below, but my heart resists MVPs, and I’m a stubborn donkey, and the design challenge at the moment is making 3-panel LED signs that can rotate their panes 180 degrees to swap between hanging or standing on a table. I think I have solved this challenge by using a PCB sandwich with 0.5 and 2.5mm thick boards, but the question remains about whether I develop that or not… My current priority is getting to a market with a decent stall, which means ironing out all sorts of bugs.

Also, I would like to embrace button head screws again: socket heads are too bulky, I feel, at the moment.

Also, I would like to experiment with two way tints… And for dust: a cover.

Programming FFTs for synesthesia

Part of the bugs mentioned above: my synesthesia mode kept crashing in the spectrogram. I traced this down to a log function and an infinite variable: solved with a try/except handler.

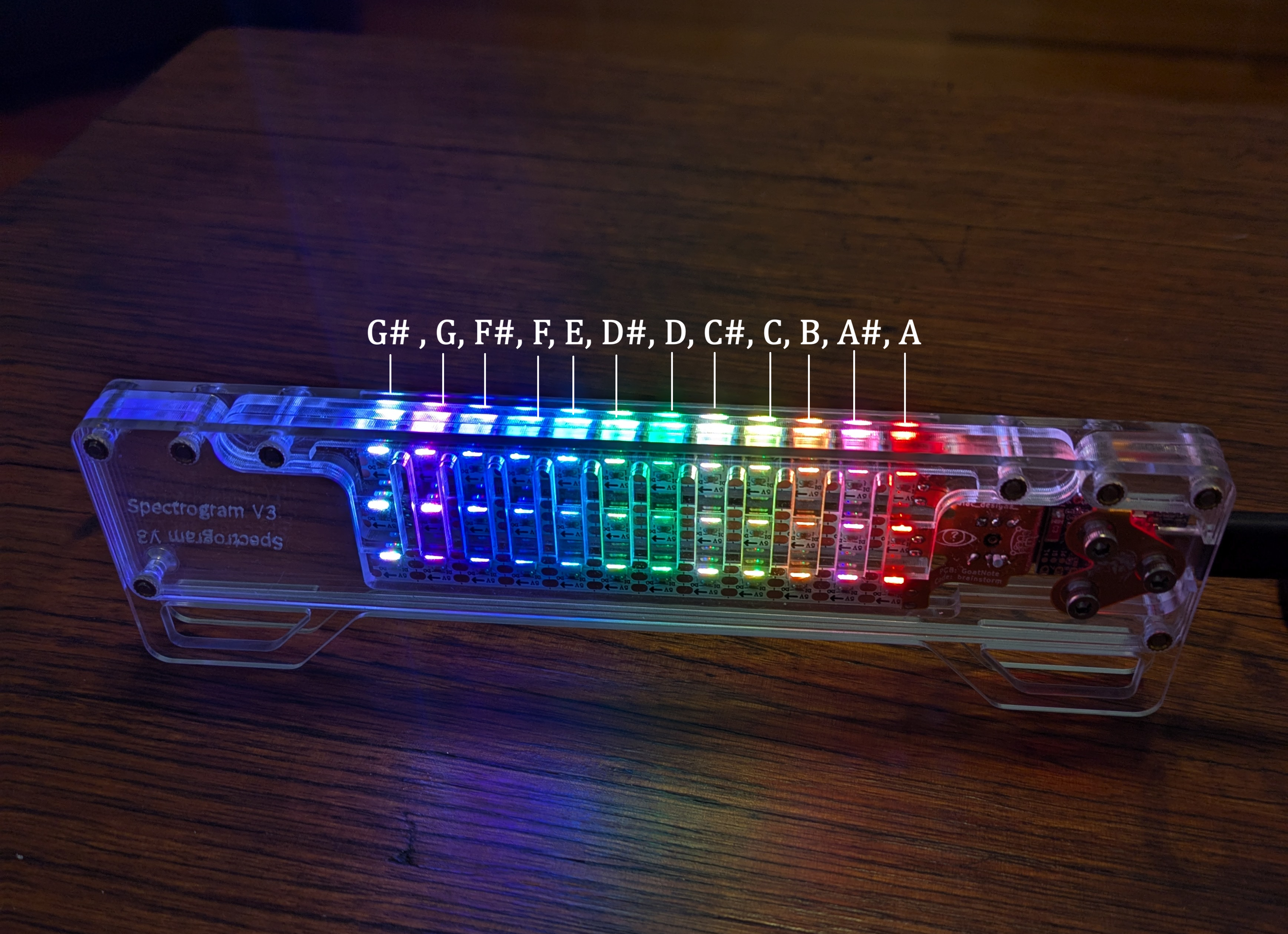

To get better differentiation of notes and colours, I spent time thinking about and picking colours to represent notes. The task was challenged by the fact that the colours change appearance when they are next to one another. My better half’s eyes strongly recommended a colour key, see aside. I thought about having a smooth spectrum of colours, but I also like the idea of sharps and flats being a less saturated version of their respective whole(?) notes. In any case, if a proficient user picks up these, they will be able to tune colours to their heart’s content: open source, baby.

Programming & Design -

more generally

Part of project Small-Medium-Large is making the spectrogram menu rescale easily, which requires me, I feel, to clean up my code a fair bit more, so I can use a config. A save and reset mode would also be great. There is also an issue with notes being assigned incorrectly, where they shouldn’t be.

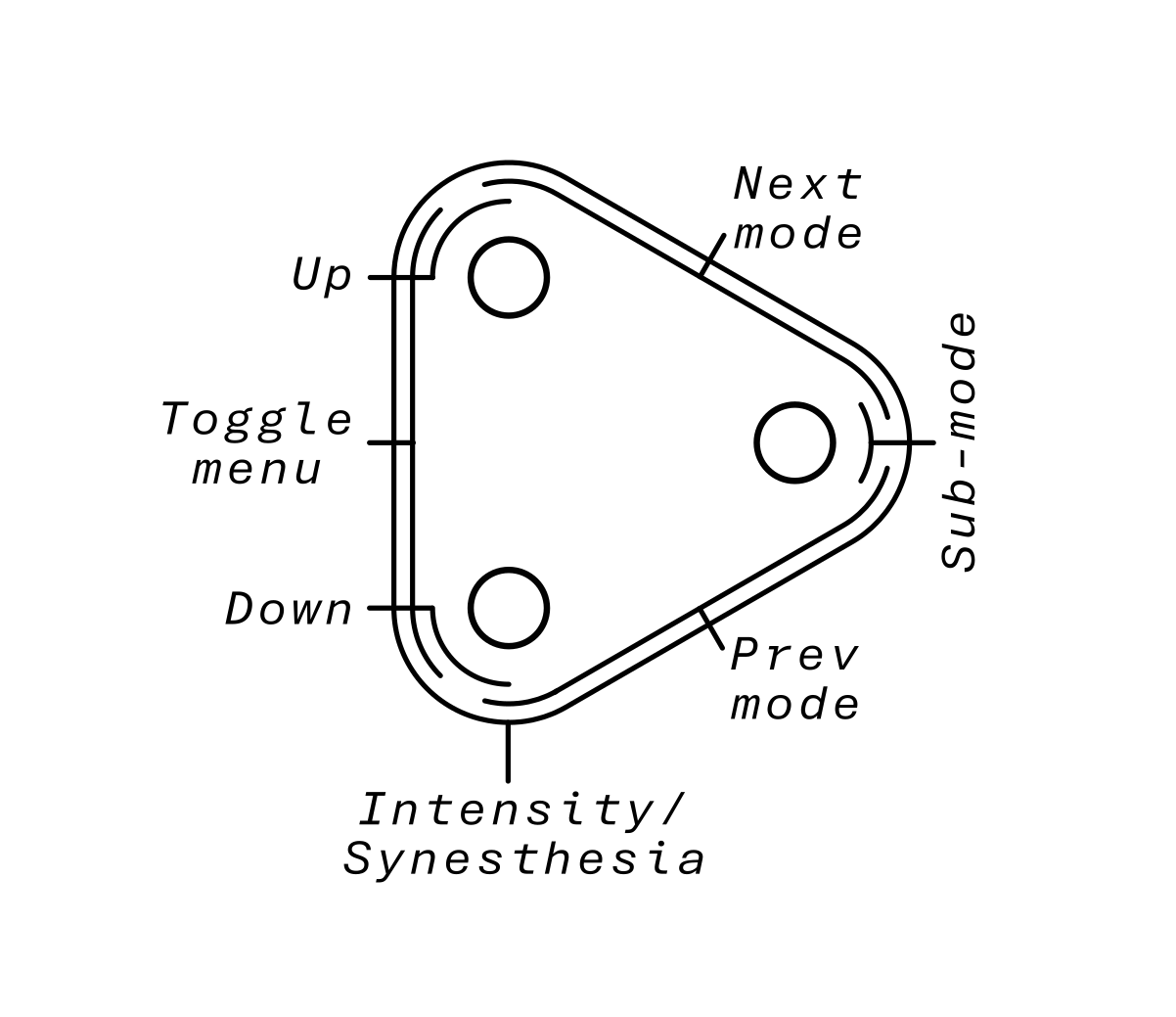

A friend quipped recently, it took them a while to learn all the new functions on their new watch, and those buttons were labelled! So I need to label non-intrusively my spectrogram, scheme proposed beside. I also need to make a manual.

Stolen musings on design for manufacture

Speaking with a colleague at the Hackerspace, some choice paraphrased quotes below:

“I keep finding myself trying to sell things when I’m not really interested in selling things”

a. Something something something - the grip of capitalism

“I’m an engineer, I love complexity. I start thinking about how to solve a problem like an engineer. But I tried thinking about how to solve problems like someone trying to sell a product, and I started thinking very differently, you start to think about design for manufacture, and you realise that the most valuable thing you have to sell is your time.”

I have been staring down projects, trying to design them for manufacture and quick assembly, while resisting the urge to make yet more PCBs, and to work around bolt placements that, frankly, need to be thought about first, before leaping onto KiCad.